Challenge / Summary:

HSE – To negate the requirement for manual extraction and handling of samples which pose a risk to personnel due to the presence of TENORM, Mercury and H2S.

Data Availability – To provide accurate PSD datasets in real-time as opposed to shipping samples onshore for lab analysis.

Solution:

- SMS mobilised and installed their Real Time Particle Size Analyser in an online, closed loop configuration to flow sample fluid from existing sample points through the analyser to closed drains.

- The package design specification incorporated a 3-phase side stream mini separator suitable for use under hazardous process conditions. The mini separator ensured samples were suspended in stable base fluid (90% water) to enable accurate particle analysis and provided necessary pressure regulation.

- A batch sampling approach was utilised whereby a known volume of liquid was flowed through the analyser flowcell and the sand particles analysed on a per well basis.

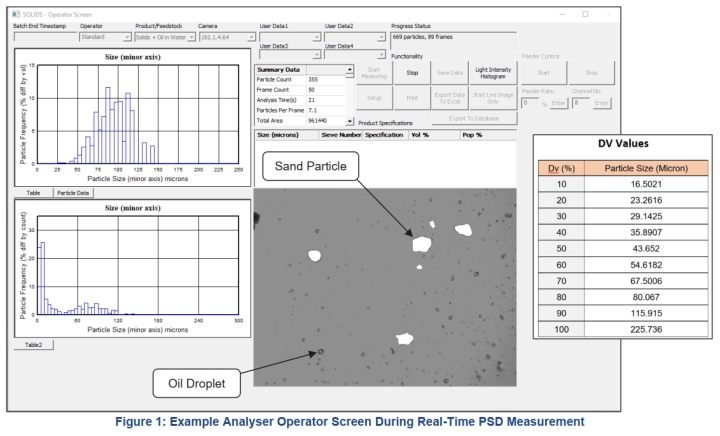

- Particles of size range 0.7 - 300 microns were analysed and the respective imaging and distribution data output to a service PC in real time

Results:

- SMS successfully conducted real-time PSD analysis for 27 wells across the field.

- Throughout all phases of the operation, PSD analysis was conducted with a minimum of 6 litres of fluid, three times per well for verification of datasets and optimised data accuracy.

- All sample imaging was recorded in the acquisition software, thus enabling results to be optimised postjob through refinement particle filter thresholding.

- Dn and Dv (%) data outputs provided the client with invaluable data to support wellhead desander design specification

Value to Client:

- Reduced HSE Risk to Personnel

- Closed loop system reducing risk of potential exposure to harmful contaminants - Reliable Real-time Data

- Immediate data analysis and availability, enabling dynamic decision making - Reduced OPEX Cost

- Minimal personnel and equipment required on-site - Repeatable and Reliable

- Batch sampling process is quickly repeatable, multiple runs per well for data averaging and obtaining representative results

- PSD data obtained direct from well flowline upstream of any process / separation

- Sufficient solids samples captured for representative sample data

Download

To download this case study please click here

Contact:

For further information contact us at This email address is being protected from spambots. You need JavaScript enabled to view it.