Our Client: Major S.E. Asia Oil and Gas Company

The Location: Offshore Malaysia

The Technical Challenge

The considerable scale of this project required multiple offshore visits, in depth onshore investigation and correlation of multiple data sets. Further to this, communicating and implementing a new strategy for the Operations team to follow going forward.

Key Facts

In order to effectively manage the project an engineer was relocated to Malaysia to be the focal point in-house to coordinate the project.

In addition to the original scope of work, SMS provided strategic input for production improvements for some wells through better and more accurate sand data analysis. Further to this we created the means for the client to maintain this optimisation through a more functional analysis technique in line with new monitoring and better data for assurance.

The sand management scope of work was aligned with a larger pilot project to digitise the field. Workflows were generated to ensure sanding wells were identified on test and managed accordingly through installation of variable chokes. Installing acoustics on the inlets of test separators was a cost effective way of monitoring and building data of multiple wells.

The Story

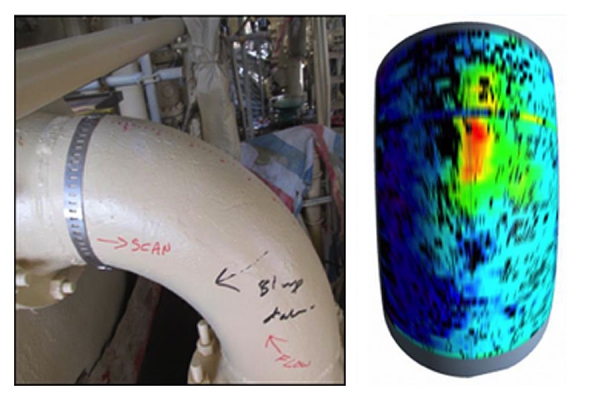

The project kicked off with data gathering both onshore and offshore. Engineers visited the offshore platforms in question and used SMS equipment to monitor every well, gathering data for the investigation. Further to this, multiple theoretical erosion calculations were performed to highlight hot spot erosion areas. This was followed by another offshore trip with SMS’ scanning technology to measure wall thickness loss on the bends identified in the theoretical study. Identification of wells producing sand, combined with erosion and deposition findings, built the foundations for the Sand Management Team to start their analysis and produce respective recommendations.

The Sand Management team utilised both experience and sand management best practice as a benchmark to understand the depth of improvement. Onshore studies were also completed in conjunction with the above. These involved interviews with operations and integrity teams to establish workflows, data gathering and processing. Following completion of the recommendations the team presented the findings to the client and developed a strategy with a supporting improvement plan for future management of sand. The client engaged the SMS team to implement the improvement plan.

Over the course of 3 months with full time support from an SMS engineer, our client turned around their sand management methods and put the necessary process and procedures in place to maintain these improvements. Further to this, the work implemented by SMS allowed the client to seek opportunities in wells with good production potential and the confidence to uplift wells they had previously been producing conservatively based on assumptions related to sand.

The sand management project was then tied in with the client’s digital oilfield and is now a key workflow for sand production.