SHARE THIS ARTICLE

CASE STUDIES

Sand Monitoring – Real Time Sanding Data Utilised to Manage Drawdown and Optimise Well Test Efficiency

Location: North Africa

Industry: International Operator

Real time sanding information was of particular importance to an international operator as it allowed them to monitor and control drawdown with respect to sand production for their open-hole completed wells, after suspending a previous well test due to tubing sand-up. Sand production was instantaneously detected at surface using ultra-sonic sand monitors and subsequent trending enabled timely decisions on drawdown and choke management to achieve maximum sand free rates for all wells. With the real-time knowledge of the wells sanding tendencies, the operator and well test company were able to optimise well test results through efficient operation of surface equipment by mitigating potential threats of erosion, sand deposition and environmental hazards.

The Technical Challenge

A well test was suspended due to lack of sanding information resulting in sand built up in tubing. It was therefore important to detect sand on surface for subsequent well tests and to determine the sanding propensity with respect to the drawdown imposed on the formation. To achieve this, reliable sand information must be available in real time so that decision that impacts on the wells’ productivity, well test data and safety could be implemented. BSW measurement would not suffice for the timely decisions required and certainly not possible at 100% gas production.

SMS Solution

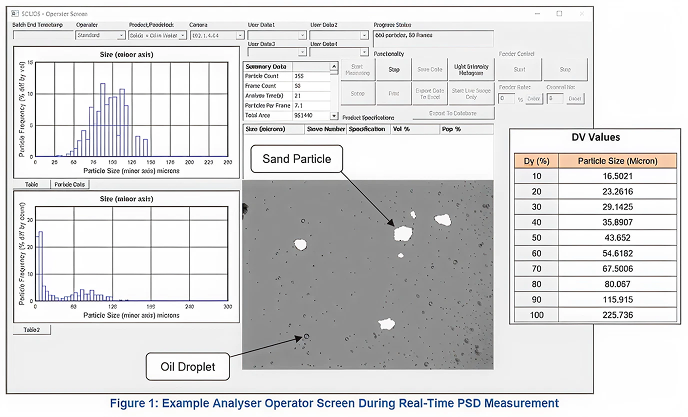

SMS deployed clamp on dual acoustic sand monitoring system located upstream and downstream of the dual pot sand trap which was part of the well test package. Sanding data from the acoustics sensors were outputted via SMS smart software located in the test company’s data acquisition unit. SMS Engineer correlated the sanding data with the wells’ flowing parameters to provide real time qualitative sanding information for managing drawdown and safely optimising equipment performance.

Value to Client

The clamp on acoustic monitoring system detected the presence of solids in the flowing fluid and the perfect match of the upstream and downstream acoustic signatures confirm solids flow through the sand trap. There was no appreciable differential pressure across the sand trap to suggest sand deposition as the grain size was much finer than the mesh size.

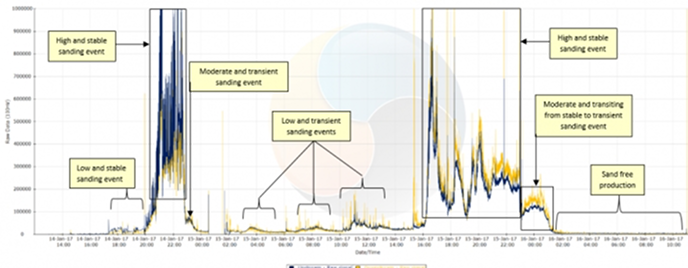

Instantaneous sanding data generated by the sensors in form of raw signals were interpreted and categorised as low, moderate or high sand production with second degree classification as transient, stable or increasing. For instance, if sand production remained constant at moderate levels, the flowing condition was kept constant for a period of time to ascertain the sanding propensity prior to any further action. However, if sand production became unacceptably high, immediate action was taken to mitigate against the potentially hazardous consequences.

The sanding information being available in real time enabled the operator to determine each well’s sanding propensity with respect to drawdown and to achieve maximum sand free rates for all wells. Also, SMS working in collaboration with the Well Test Company and the operator utilised the sanding information to safely optimise the efficiency of surface equipment for best well test results.

To find out how SMS can add value to your well test, just get in touch info@smsintegrity.com

Real time sanding information was of particular importance to an international operator as it allowed them to monitor and control drawdown with respect to sand production for their open-hole completed wells, after suspending a previous well test due to tubing sand-up. Sand production was instantaneously detected at surface using ultra-sonic sand monitors and subsequent trending enabled timely decisions on drawdown and choke management to achieve maximum sand free rates for all wells. With the real-time knowledge of the wells sanding tendencies, the operator and well test company were able to optimise well test results through efficient operation of surface equipment by mitigating potential threats of erosion, sand deposition and environmental hazards.

The Technical Challenge

A well test was suspended due to lack of sanding information resulting in sand built up in tubing. It was therefore important to detect sand on surface for subsequent well tests and to determine the sanding propensity with respect to the drawdown imposed on the formation. To achieve this, reliable sand information must be available in real time so that decision that impacts on the wells’ productivity, well test data and safety could be implemented. BSW measurement would not suffice for the timely decisions required and certainly not possible at 100% gas production.

SMS Solution

SMS deployed clamp on dual acoustic sand monitoring system located upstream and downstream of the dual pot sand trap which was part of the well test package. Sanding data from the acoustics sensors were outputted via SMS smart software located in the test company’s data acquisition unit. SMS Engineer correlated the sanding data with the wells’ flowing parameters to provide real time qualitative sanding information for managing drawdown and safely optimising equipment performance.

Value to Client

The clamp on acoustic monitoring system detected the presence of solids in the flowing fluid and the perfect match of the upstream and downstream acoustic signatures confirm solids flow through the sand trap. There was no appreciable differential pressure across the sand trap to suggest sand deposition as the grain size was much finer than the mesh size.

Instantaneous sanding data generated by the sensors in form of raw signals were interpreted and categorised as low, moderate or high sand production with second degree classification as transient, stable or increasing. For instance, if sand production remained constant at moderate levels, the flowing condition was kept constant for a period of time to ascertain the sanding propensity prior to any further action. However, if sand production became unacceptably high, immediate action was taken to mitigate against the potentially hazardous consequences.

The sanding information being available in real time enabled the operator to determine each well’s sanding propensity with respect to drawdown and to achieve maximum sand free rates for all wells. Also, SMS working in collaboration with the Well Test Company and the operator utilised the sanding information to safely optimise the efficiency of surface equipment for best well test results.

To find out how SMS can add value to your well test, just get in touch info@smsintegrity.com