SMS Team / April 4, 2018

Everyone is telling me that the robots are coming to steal our jobs. Whether it is in the media or on LinkedIn everyone is talking about automation. Automation is driving efficiency in the oil industry but also causing a reduction in jobs. Well there are some jobs which I am happy for a robot to do instead of me. Ever since I started working the oil industry I have always had a fearful respect for H2S. This probably stems from my early days as a well site chemist.

My very first well test was on the Buzzard field in the North Sea. A field which is known to have high concentrations of H2S, concentrations over 1200 ppm. As a well test chemist it was my duty to carry out UOP 212-77 analysis to determine the H2S content in the gas stream. This involved trapping the sulphides and then performing a titration. Working in the high H2S environment required full breathing apparatus to be worn for the full duration of the shift which was energy sapping. Don’t think my back fully recovered. We were also required to carry out the titrations whilst wearing breathing apparatus which in the confines of a small lab cabin resulted in broken glass beakers and burettes and a lot of swearing.

Later in my career I was required to undertake sand monitoring on a high profile sour gas well testing project in UAE. A project which a few years earlier would not have been possible. The advances in technology meant that they were able to test wells which were in the 40 % H2S concentration range. We did though experience a gas leak which had me and my colleagues donning breathing escape sets and climbing the sand dunes to evacuate the wellsite. Since that episode I have always respected sour gas operations.

H2S concentration is an Important measurement during well test operations. It is vital for safe well operations, well construction and asset integrity to know the concentration of H2S in the produced hydrocarbons. Traditional methods of measuring H2S on well tests involve gas detection tubes and gas sampling. Both require a skilled operator working in a hazardous area. Human error is very much a factor in the quality and accuracy of the readings taken. I have seen operators taking readings by pulling gas detection tubes without using a bladder to condition the gas or even measuring the fresh air over the sample point. None of these methods will provide an accurate reading.

Gas analysis can be undertaken in a laboratory where it is flashed off and GC analysis undertaken to provide an accurate measurement. Once again, the weakness in this analysis is the human factor. You rely on a skilled engineer taking a good representative sample. Similarly, in theory H2S concentration should not change whilst the gas is transported in a sample cylinder. Although in practise this is not always the case as the metal cylinders can absorb the sample even though those which have been conditioned resulting in an inaccurate measurement.

Using humans to take samples for H2S measurements is extremely hazardous and highly inaccurate. There are now many online applications where H2S can be measured in real time. Whether it is acetate tape absorbance spectrophotometry or Tuneable Laser Diode, all these methods can provide operators with reliable data to make informed operational decisions. Real time H2S monitoring is the future it can provide accurate and safe data.

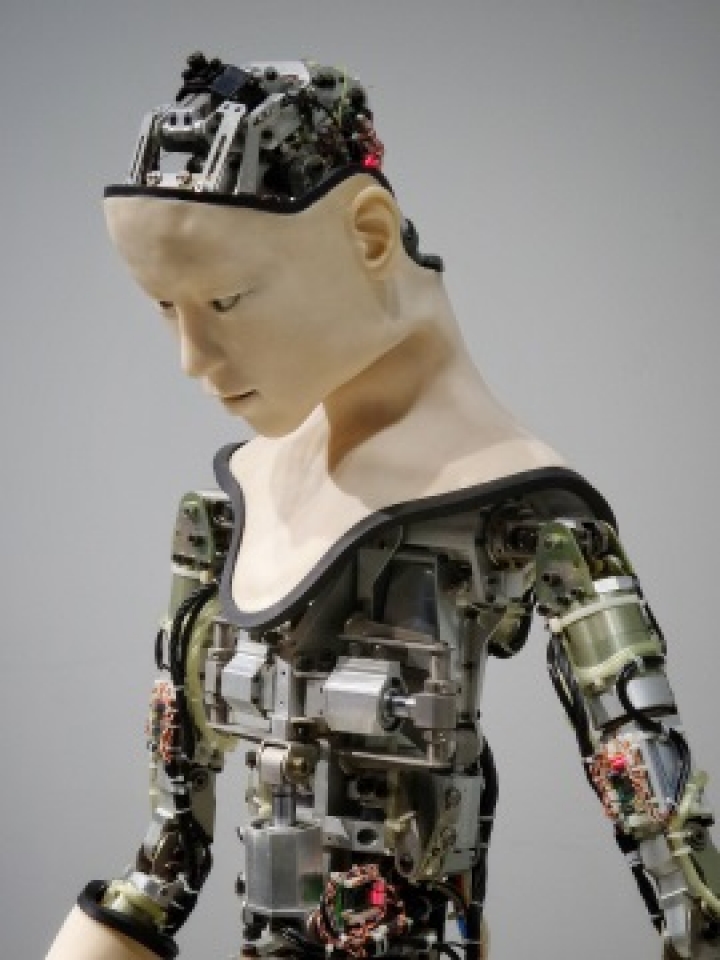

Whilst there are some applications where I would fear automation in terms of my career. H2S measurements is not one of them. So I say let the robots come!