SHARE THIS ARTICLE

CASE STUDIES

Frac Ops – Tight Gas Field

Location: Middle East

Industry: An International Oil & Gas Service Provider

Sensing and analytics packages integrated seamlessly for remote access and results visualisation.

We delivered a comprehensive service platform integrating cutting edge instrument technology and software capability to collect, connect and integrate data for our client. This resulted in increased uptime and operational efficiency.

The Technical Challenge and Workscope

1. Management of integrity threats during Frac stimulation operations

2. Risk

Integrity risk to piping system, potential for loss of life, serious injury, disruption and delays to operation and unplanned costs.

3. Mitigation

Integrated package for well service flow assurance incorporating cutting edge sensing tech, software hub and interactive reporting modules:

- Acoustic “Sand” Sensors

- Intrusive Erosion Probes

- Wireless Online

- 3D Wall Mapping for full visualisation of at-risk locations

What We Did

- Integrated multisensor arrays in three well test packages across field development

- Collated sensor data streams and integrated into vendor acquisition system

- Produced daily well site integrity report for client highlighting critical events to safeguard plant and provide effective risk mitigation.

Integrated sensing and analytics:

– Wireless and wired sand and corrosion sensors

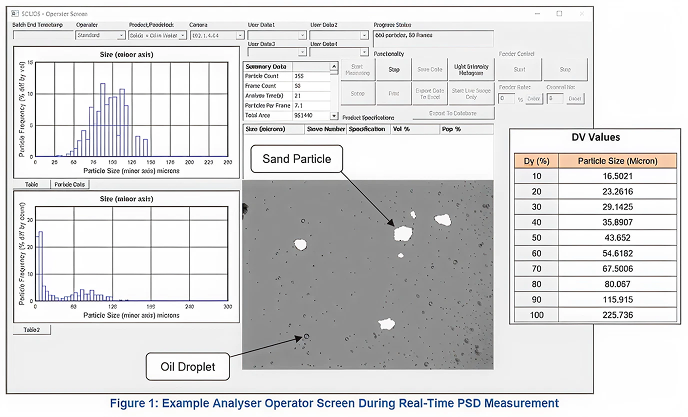

– Particle sampling and lab analysis

– 3D wall thickness mapping

– Oil in water

– H2S/CO2

– Hydrates

Integration software hub

Visualisation and data management

What We Achieved

- No LOC’s to plant on successful implementation

- Minimised the potential of injury to operators

- Optimised cyclone operations

- Increased uptime and operational efficiency.

Sensing and analytics packages integrated seamlessly for remote access and results visualisation.

We delivered a comprehensive service platform integrating cutting edge instrument technology and software capability to collect, connect and integrate data for our client. This resulted in increased uptime and operational efficiency.

The Technical Challenge and Workscope

1. Management of integrity threats during Frac stimulation operations

2. Risk

Integrity risk to piping system, potential for loss of life, serious injury, disruption and delays to operation and unplanned costs.

3. Mitigation

Integrated package for well service flow assurance incorporating cutting edge sensing tech, software hub and interactive reporting modules:

- Acoustic “Sand” Sensors

- Intrusive Erosion Probes

- Wireless Online

- 3D Wall Mapping for full visualisation of at-risk locations

What We Did

- Integrated multisensor arrays in three well test packages across field development

- Collated sensor data streams and integrated into vendor acquisition system

- Produced daily well site integrity report for client highlighting critical events to safeguard plant and provide effective risk mitigation.

Integrated sensing and analytics:

– Wireless and wired sand and corrosion sensors

– Particle sampling and lab analysis

– 3D wall thickness mapping

– Oil in water

– H2S/CO2

– Hydrates

Integration software hub

Visualisation and data management

What We Achieved

- No LOC’s to plant on successful implementation

- Minimised the potential of injury to operators

- Optimised cyclone operations

- Increased uptime and operational efficiency.